Three-Point Hitch

The three-point hitch is a standardized method of attaching implements (equipment) to tractors, first developed by Harry Ferguson in the 1920s. The three-point hitch uses two lower connection points and one upper point which provides a rigid connection. Hydraulic cylinders operate on the lower arms to raise and lower the implement. An additional hydraulic arm may act on the upper arm to control the draft (depth) of tillage equipment. A significant advantage of the three-point hitch is that it converts the drag of the equipment into a downward force on the rear of the tractor. This means that the traction is maximized when the pulling is most difficult.

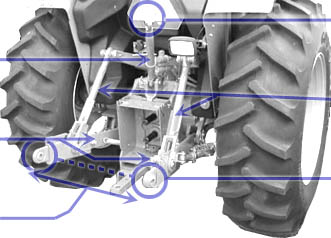

Three-point hitch components

| Upper hitch point | |

| Upper link arm | ||

| Lift arms | ||

| Lower link arms | ||

| Lower hitch points | ||

| Lower point span |

Three-point hitch specifications

| Category | Hitch pin size | Lower hitch spacing | Tractor drawbar power | |

| upper link | lower links | |||

| 0 | 17 mm (5⁄8") | 17 mm (5⁄8") | 500 mm (20") | <15 kW (<20 hp) |

| 1 | 19 mm (3⁄4") | 22.4 mm (7⁄8") | 718 mm (28") | 15-35 kW (20-45 hp) |

| 2 | 25.5 mm (1") | 28.7 mm (1 1⁄8") | 870 mm (34") | 30-75 kW (40-100 hp) |

| 3 | 31.75 mm (1 1⁄4") | 37.4 mm (1 7⁄16") | 1010 mm (40") | 60-168 kW (80-225 hp) |

| 4 | 45mm (1 3⁄4") | 51 mm (2") | 1220 mm (48") | 135-300 kW (180-400 hp) |

History

The modern three-point hitch began with experiments by Harry Ferguson in the 1920s and 1930s. During World War I, Ferguson served as a sales agent in Ireland for the Overtime tractors, which were imported Waterloo Boys. This period provided Ferguson with considerable experience at the start of mechanized farming in Ireland and England. Most early tractor plows were trailer-mounted and merely pulled behind the tractor. Often, the biggest problem was not the raw power of the tractor, but gaining enough traction to put the power to use. Early tractors were very heavy and employed steel lugs to try and achieve enough traction.

Ferguson began experimenting with mounted plows while working for the Irish Board of Agriculture. His early work with mounted plows used a modified Ford model T automobile and later a Fordson model F tractor. Ferguson's mounting system evolved from two link arms (one top, one bottom) to three, and from spring-assisted lift to hydraulics. He met with a number of tractor manufacturers and eventually reached a deal with David Brown in 1933, resulting in the production of the Ferguson-Brown model A, with Ferguson's three-point system. By 1937, however, poor sales and disagreements between Ferguson and Brown caused production to stop.

In the autumn of 1938, Ferguson met with Henry Ford to demonstrate his tractor and hitch system. Ferguson impressed Ford enough to enter into a production agreement (known as the "handshake agreement", because very little of the business arrangments were formalized on paper). The result was the Ford model 9N in 1939. The N-series tractors became a great success for Ford. In 1947, Henry Ford II was in control of Ford and decided continue production without Ferguson's involement. Ferguson began production with another company (Ferguson Tractor, which joined with Massey-Harris in 1959). Ford eventually settled a lawsuit with Ferguson for over $9 million, but it was the beginning of the end for Ferguson's exclusive control over his three-point system.

The success of the three-point hitch on Ford N-series tractors led other manufacturers to begin building their own versions of the hitch. Most major manufacturers developed a a similar hitch, each with variations to avoid violating Ferguson's patents. By 1960, Ferguson's patents had expired and a judge refused to extend them, noting their value to agriculture. The three-point hitch specifications became standardized in the industry by American Society of Agricultural Engineers (ASAE S217) and, later, the International Organization for Standardization (ISO 730-1).

©2000-2025 - TractorData.com®. Notice: Every attempt is made to ensure the data listed is accurate. However, differences between sources, incomplete listings, errors, and data entry mistakes do occur. Consult official literature from the manufacturer before attempting any service or repair.